Recent Posts

- Peace Through Water Desalination

- CPAC Water Policy Interview with KLRN Radio San Antonio Texas

- CPAC Water Interview With California Talk Show Host Rick Trader

- Toward a Green Earth Policy in the era of Trump

- Gates Foundation Water Energy Vision

Recent Comments

- on LLNL Researchers use carbon nanotubes for molecular transport

- on Greenhouses for Desalination

- on American Membrane Technology Association

- on Engineers develop revolutionary nanotech water desalination membrane

- on LLNL Researchers use carbon nanotubes for molecular transport

Archives

- May 2017

- March 2017

- June 2011

- December 2008

- November 2008

- October 2008

- September 2008

- August 2008

- July 2008

- June 2008

- April 2008

- February 2008

- January 2008

- December 2007

- November 2007

- October 2007

- September 2007

- August 2007

- July 2007

- June 2007

- May 2007

- April 2007

- March 2007

- February 2007

- January 2007

- December 2006

- November 2006

- October 2006

- September 2006

- August 2006

- July 2006

- June 2006

Categories

Mind the gap: New information on the hydrophobic water gap

23rd March 2007

This is useful info to anyone doing membrane research. The key take away is that water molecules keep a distance of one molecule diameter from a water repelling surface. The article is here, as well as below.

Mind the gap: New information on the hydrophobic water gap

Gap between the ordered molecules of a hydrophobic layer and water. The water molecules keep a distance of about one molecular diameter. Credit: Max Planck Institute

Researchers have found a gap between water and a water-repelling surface that can give new insight into the way water and oil separate. By using high-energy X-rays at the ESRF, an international team defined the size and characteristics of this gap. The knowledge of the structure of a hydrophobic interface is important because they are crucial in biological systems, and can give insight in protein folding and stability. The researchers publish their results this week in PNAS Early Online Edition.

The repulsion of water is a phenomenon present in many aspects of our lives. Detergent molecules made up of components attracted to water (hydrophilic) and others that repel it (hydrophobic). Proteins also use the interaction with water to assemble into complexes. However, studying hydrophobic structures and what occurs when they encounter water is not entirely straightforward as it is influenced by certain factors. Early studies of the gap formed between water and a hydrophobic surface did not show a coherent picture.Scientists from the Max Planck Institute for Metals Research (Germany), the University of South Australia (Adelaide) and the ESRF carried out experiments on silicon wafers covered by a water-repulsive layer at the surface. The wafers were then immersed in water by a special cell. Studies of the water structure at the interface of the hydrophobic layer confirmed that a gap is formed between the layer and water and that its size is the diameter of a water molecule, somewhere between 0.1 and 0.5 nanometer. The integrated density deficit at the interface amounts to half a monolayer of water molecules.The scientists did further experiments in order to test the influence of gas, which is naturally present in water, on the hydrophobic water gap. During all their experiments they kept the water ultra clean (unlike water in nature) and they introduced gas into the cell until saturation. The result shows that, contrary to previous reports, gas does not play a role in the structure of water at flat interfaces. This is the first time that high energy synchrotron X-rays have been used as a tool to measure the properties of this gap. “Some teams have used neutrons, but they didn’t have enough resolution, after all, the gap is extremely small and difficult to track,” explained Harald Reichert, the paper’s corresponding author. Despite the superior quality of the X-ray beam, the experiment was still a challenge: the water-repellent layer on the silicon wafer can survive only 50 seconds under the beam, so measurements had to be completed very quickly.

The next step for the team is to produce porous structures and study the properties of water at confined pore interfaces. “These studies will increase our knowledge of how water behaves in different environments. The structure of water in these environments is still, somewhat a mystery to us, despite the fact that our world is surrounded by water”, declared Reichert.

Source: European Synchrotron Radiation Facility

This news is brought to you by PhysOrg.com

New Water Modeling Tool

23rd March 2007

This water modeling tool might be useful:

The first comes from Researchers at the University of Delaware:

Equipped with high-speed computers and the laws of physics, scientists from the University of Delaware and Radboud University in the Netherlands have developed a new method to “flush out” the hidden properties of water–and without the need for painstaking laboratory experiments.

The UD researchers used clusters of Linux computers to perform the large-scale computer calculations required for the research. The study took several months to complete.

The result is a new model — the first that can accurately predict both the properties of a pair of water molecules and of liquid water.

Among its many applications, the research should help scientists better understand water in not only its liquid form, but in other states as well, such as crystalline forms of ice, and water in extreme conditions, including highly reactive “supercritical” water, which is used to remove pollutants in wastewater and recover waste plastic in chemical recycling, Szalewicz said.

The model might also be used to model H2O in solution with Na & Cl. Anyhow, there ought to be a way for desalination researchers to make use of the new modeling tool on request.

The rest of the article can be found here.

Fluid dynamics theory works on nanoscale outside vacuum

23rd March 2007

I mentioned last October at the end of a post that:

Penny Smith, a mathematician at Lehigh University, has posted a paper on the arXiv that purports to solve one of the Clay Foundation Millenium problems, the one about the Navier-Stokes Equation. The paper is here, and Christina Sormani has set up a web-page giving some background and exposition of Smith’s work.

There’s further work here.

Fluid dynamics theory works on nanoscale outside vacuum

A propane liquid nanobridge breaks up in a nitrogen gas environment. Credit: Georgia Tech/Uzi Landman

In 2000, Georgia Tech researchers showed that fluid dynamics theory could be modified to work on the nanoscale, albeit in a vacuum. Now, seven years later they’ve shown that it can be modified to work in the real world, too – that is, outside of a vacuum. The results appear in the February 9 issue of Physical Review Letters.

It’s well-known that small systems are influenced by randomness and noise more than large systems. Because of this, Georgia Tech physicist Uzi Landman reasoned that modifying the Navier-Stokes equations to include stochastic elements – that is give the probability that an event will occur – would allow them to accurately describe the behavior of liquids in the nanoscale regime.

Writing in the August 18, 2006, issue of PRL, Landman and post doctoral fellow Michael Moseler used computer simulation experiments to show that the stochastic Navier-Stokes formulation does work for fluid nanojets and nanobridges in a vacuum. The theoretical predictions of this early work have been confirmed experimentally by a team of European scientists (see the December 13, 2006, issue of Physical Review Letters). Now, Landman and graduate student Wei Kang have discovered that by further modifying the Moseler-Landman stochastic Navier-Stokes equations, they can accurately describe this behavior in a realistic non-vacuous environment.

To read the full article go here.

Nanotube formation captured on video

23rd March 2007

Nanotube formation captured on video. (click here for video)

A Cambridge University-led team of scientists have successfully produced live video footage that shows how carbon nanotubes, more than 10,000 times smaller in diameter than a human hair, form.

The video sequences show nanofibres and nanotubes nucleating around miniscule particles of nickel and are already offering greater insight into how these microscopic structures self-assemble. The films can be viewed on the Cambridge University website.

In particular, the team discovered that the carbon network is guided into tubular shape by a drastic restructuring of the nickel – the catalyst in the process. They were also able to track and time the deposition of the carbon around the nickel.

Carbon nanotubes are new building blocks enabling engineers to improve and further miniaturise everyday electronic devices like computers or mobile phones. At the moment scientists can grow nanotubes but cannot accurately control their structure.

Being able to do so is vital as it is the very structure of a nanotube that dictates its properties. The nano-scale video observations mean that scientists will be able to better understand the nucleation of nanotubes and are therefore an important step on the route towards application.

The two sequences show action taking place in real time on an astonishingly small scale. The difference in size between a single-walled nanotube and a human hair is close to the difference between the same human hair and the Eiffel Tower. The microscopic scale involved has, in the past, made it difficult to understand the growth process.

The team used X-rays produced at a synchrotron (a type of particle accelerator) and a modified high-resolution transmission electron microscope to observe and film a process called catalytic chemical vapour deposition. This is one of several methods of producing nanotubes, and involves the application of a gas containing carbon (in this case acetylene) to minute crystalline droplets referred to as “catalyst islands” (the nickel).

As the gas is applied carbon sticks to the catalyst islands forming layers of graphite. In conditions appropriate to creating nanofibres, the nickel particle was pushed upwards in a series of peristaltic movements as the carbon continued to deposit on its sides. At several points the nickel formed a cap which almost “popped” out of the forming tube, leaving a layer of graphite behind it. This process is called “bambooing”, because the resultant carbon nanofibre is a cylinder containing several cavities, each one separated by one of these graphite layers, similar in form to bamboo. Throughout the whole process, the nickel remained crystalline rather than liquid.

The team then looked at conditions more appropriate to producing single-walled carbon nanotubes, which involved less acetylene. The catalyst is not squeezed upwards. Instead, a cap of carbon formed on the top of the nickel, and gradually extended from it to form a tubular structure. The catalyst island was squeezed and reshaped by this process and was moulded by the carbon forming around it rather than retaining its original form.

Dr Stephan Hofmann, who led the research, said: “In order to reach the full application potential for nanotubes, we need to be able to accurately control their growth first. As a manifestation of the impressive progress of nanometrology, we are actually now able to watch molecular objects grow. This new video footage shows that the catalyst itself remains crystalline but is constantly changing its shape as the carbon network is formed around it.

“We cannot yet solve the problem of not being able to self-assemble carbon nanotubes with well-defined characteristics, but we have discovered that if we are to do so, we need to be mindful not just of the carbon dynamics but the changing shape of the catalyst as well.”

Making Biofuel from Pond Scum with Fresh Water Byproduct

16th March 2007

According to this CSRwire press release this week–“In-Flight Media has produced an impressive current-event documentary type two-minute video clip for GSPI. The video illustrates a solution to both solving the fuel crisis and global warming crisis simultaneously”–(if you believe in CO2 as the cause of global warming–which I don’t) . “Over 5-million people will view this video on Continental Airline flights during the months of April and May (2007). A preview of this video is presently available for viewing at” http://video.google.com/videoplay?docid=595872956429027619.

I have written several pieces on using desalinising greenhouses for dual use desalination and biodiesal

The article below fleshes out the algae-to-biodiesal angle pretty well. What the article doesn’t mention is that Greenfuels is now running second stage tests in Arizona using “greenhouse-like buildings about 30 feet wide by 500 feet long that will house the algae”. Future algae greenhouses could use Seawater Greenhouse desalination technology. This would be especially appropriate for areas in the southwest that have carbon dioxide producing plants sited above briny aquifers–or areas along the US coasts that use coal to produce electricity. As well, here is an article that says adding hydrogen to biomass — while its being turned into fuel — increases efficiencey significantly. The process is a “hybrid hydrogen-carbon process,” (H2CAR). According to this article the Hydrogen-Augmented Fischer-Tropsch Processes yields More Product, No CO2.

The new approach modifies conventional methods for producing liquid fuels from biomass by adding hydrogen from a “carbon-free” energy source, such as solar or nuclear power, during a step called gasification. Adding hydrogen during this step suppresses the formation of carbon dioxide and increases the efficiency of the process, making it possible to produce three times the volume of biofuels from the same quantity of biomass.

The picture looks like this:

That would increase the output of greenhouses turning algae to biodiesal significantly. (Same goes for thermal depolymerization.) Further, solar panels mentioned here will come onstream next fall at 1/10 current costs to convert sunlight to electricity for electrolysis to produce hydrogen for the process mentioned above.

While this talk is about fuel–it should be mentioned that the by product is… fresh water.

The article below mentions that they expect the algae to yield biodiesal for $50@ barrel. I think those numbers will fall.

January 26, 2007

Making Biofuel from Pond Scum

Oil-rich plants such as soy may offer a cleaner energy alternative to diesel fuel, but Jim Sears says these food crops can’t meet all our diesel needs. The Colorado-based entrepreneur says, even in America’s bountiful croplands, farmers couldn’t grow enough oilseed crops to meet demand.

“It is about 1,000 times more efficient to produce fuel from algae than it is from an irrigated crop. There’s enough water even in the desert from natural rainfall to support this technology.”

— Jim Sears, Solix Biofuels, Founder

“Right now,” [Sears] points out, “if we were to use all the normal sources we know about, such as canola oil, soy, things like this to make biodiesel, the industry thinks they could make 3.7 billion liters a year. That sounds like a lot, but Americans currently use 227 billion liters of diesel a year.”Fortunately, Sears says, an unconventional crop could produce 100 times more biodiesel per hectare than either canola or soy. It can thrive in places where other crops can’t grow at all, and it only requires the equivalent of 5 centimeters of rain a year. It’s algae, a small but familiar plant, usually seen as a green scum that forms on ponds or aquarium glass.

To demonstrate his crop’s potential, Sears leads the way inside a former coal-fired electric power plant, now the Engines and Energy Conversion Laboratory at Colorado State University (CSU). CSU and Sears’ small company, Solix Biofuels, have teamed up for this research.

Sears passes a two-story tall engine that may soon be running on his biodiesel, and heads to a quieter room where test batches of algae grow in glass beakers. The water ranges from pale yellow to soft Irish green, thanks to millions of microscopic algae.

Biologist Nick Rancis lifts a favorite specimen. “Here we have a species of green algae that grows in fresh water. As you can see, it grows very high density. You can’t even see through it when you hold it up to the light.” He says this strain produces enormous amounts of fat: up to 50 percent of its body weight. And while producing oil from soy or canola generally requires a three to five-month growing season, some algae are so prolific, over half a batch can be harvested for oil production every day. “They can double or triple overnight,” Rancis says.

For industrial production, the researchers are designing enormous growing troughs, wider than two trucks side by side, as long as a football field, and grouped by the thousands around processing plants. In this way, Sears says, algae could supply all the U.S. diesel power on a fraction of the nation’s farmland, just one percent of the 400 million hectares now under cultivation.

“Actually we wouldn’t have to convert any of our arable land,” [Sears] observes. “We could use desert land to grow this algae. It doesn’t require good soil. Just flat land, carbon dioxide and sunlight.”

Carbon dioxide helps algae grow fast and fat, so the team plans to siphon it from fossil fuel power plant exhaust, which will reduce greenhouse gas emissions. And Sears says there are other ways to get the gas. “It would actually start with biomass such as switch grass or wood, where in some countries are the only type of fuel that they have anyway. In that case, the grass, the trees, the wood is pulling the carbon dioxide out of the air, then we burn it as fuel and feed the carbon dioxide to the algae.”

He stresses that no carbon will be added to the atmosphere during all these energy conversion steps, making biofuel from algae is a truly carbon-neutral technology. “It’s essentially solar powered fuel.”

To conserve water, the growing troughs are sealed. The algae grows under a clear plastic lid that allows in plenty of sunlight, but keeps the water the plants are floating in from evaporating. “It is about 1,000 times more efficient to produce fuel from algae than it is from an irrigated crop,” Sears says. “There’s enough water even in the desert from natural rainfall to support this technology.”

Affordable biodiesel is an important focus of the research team, and Bryan Willson, who directs this Engines and Energy Conversion Lab, says the projections look promising. “We believe the technology could be cost competitive with $50 a barrel oil, which is basically where we are right now. Even last year, we were up to $70 a barrel.”

Because building a vast new production system is an enormous undertaking, Sears predicts that it will be five to ten years before biodiesel from algae becomes commonplace. However, Eric Jarvis, a senior scientist at the National Renewable Energy Lab, cautions that it may take longer. “I wouldn’t expect it to meet a large demand for diesel in that time frame, but I’m hoping to see some good demonstration projects in the next 5 to 10 years.” He adds that in the last two years, interest in developing systems for biodiesel from algae has grown tremendously, and he gets phone calls every week from people trying to get into this area.

Whether it takes five years, a decade or a little longer, Jim Sears says he’s certain that biodiesel from algae will become commonplace. He calls it “by far the most scalable and reasonable way to make biofuels in the future in an endlessly sustainable method.”

As he considers that future, a train whistle sounds in the distance. “That train is the train that used to bring the coal to this power plant,” he comments, adding “it is one of the future customers.”

The National Renewable Energy Lab plans to step up their development of biodiesel from algae within the year, and they estimates that along with Colorado State and Solix Biofuels, roughly a dozen other groups around the world are developing similar projects, increasing the likelihood that someday soon, clean-burning algae biodiesel will be the fuel of choice for trucks, boats . . . and trains.

Hydrogen Catalyst Tools at Argonne For Desalination

09th March 2007

imho there should be a desal lab in the USA working on desalination catalysts. If there isn’t one — then a couple scientists should be funded. The tools they would use are being developed for hydrogen catalysts over at Argonne Labs. Notice how the article below mentions how their tools & methodologies can be applied to other things beside hydrogen catalysts. Read the piece and consider: aren’t the issues here similiar to those of desalination and wouldn’t it be nice to develop a catalyst that would just settle the salt out of solution or make the Na & Cl ions bind so they can’t pass through a semi permiable membrane? Anyhow here’s the article:

|

|||||

|

This news is brought to you by PhysOrg.com |

Is it Possible Graphene Could Be Used For Desalination?

02nd March 2007

There have been a couple of articles over the last year on the use of “graphene-based materials.” Graphene is interesting because– rolled up its a carbon nanotubes. However, laid out flat — its graphene — and it is cheap and plentiful.

Work appeared out of Northwestern last year:

“This research provides a basis for developing a new class of composite materials for many applications, through tuning of their electrical and thermal conductivity, their mechanical stiffness, toughness and strength, and their permeability to flow various gases through them,” said Ruoff, professor of mechanical engineering in the McCormick School of Engineering and Applied Science. “We believe that manipulating the chemical and physical properties of individual graphene-based sheets and effectively mixing them into other materials will lead to discoveries of new materials in the future.”

Another team led by Andre Geim from the University of Manchester in England:

But Geim and colleagues say that the appeal of this kind of carbon lies not with nanotubes in themselves, but with the underlying fabric: the flat sheets of graphene. They have developed methods for splitting graphite apart into its separate layers and lying them down flat on a surface, where their electrical properties can be studied. A graphene sheet is electrically conducting, behaving essentially like a two-dimensional metal. But it is a strange kind of metal, with properties dictated by quantum mechanics. For example, even if there are no mobile electrons to carry an electrical current, the electrical conductivity can never fall below a certain minimum value: it is like an electron gate that can never be fully closed.

And the Manchester researchers have shown that graphene can be fashioned into a device called a spin valve, which discriminates between mobile electrons according to their spin.

Maybe too this could be worked into a filter of some sort to take out charged Na or Cl ions.

This week another article came out on the subject:

Physicists pioneer new super-thin technology (Update)

Atomic gauze hanging on a scaffold of golden wires: It is the thinnest material you will ever see. Credit: University of Manchester

Researchers have used the world’s thinnest material to create a new type of technology, which could be used to make super-fast electronic components and speed up the development of drugs.

Physicists at The University of Manchester and The Max-Planck Institute in Germany have created a new kind of a membrane that is only one atom thick.

An artist’s impression of the chicken wire of carbon atoms. Credit: University of ManchesterIt’s believed this super-small structure can be used to sieve gases, make ultra-fast electronic switches and image individual molecules with unprecedented accuracy.

The findings of the research team is published today in the journal Nature.

Two years ago, scientists discovered a new class of materials that can be viewed as individual atomic planes pulled out of bulk crystals.

These one-atom-thick materials and in particular graphene – a gauze of carbon atoms resembling chicken wire – have rapidly become one of the hottest topics in physics.

However, it has remained doubtful whether such materials can exist in the free state, without being placed on top of other materials.

Now an international research team, led by Dr Jannik Meyer of The Max-Planck Institute in Germany and Professor Andre Geim of The University of Manchester has managed to make free-hanging graphene.

The team used a combination of microfabrication techniques used, for example, in the manufacturing of microprocessors.

A metallic scaffold was placed on top of a sheet of graphene, which was placed on a silicon chip. The chip was then dissolved in acids, leaving the graphene hanging freely in air or a vacuum from the scaffold.

The resulting membranes are the thinnest material possible and maintain a remarkably high quality.

Professor Geim – who works in the School of Physics and Astronomy at The University of Manchester – and his fellow researchers have also found the reason for the stability of such atomically-thin materials, which were previously presumed to be impossible.

They report that graphene is not perfectly flat but instead gently crumpled out of plane, which helps stabilise otherwise intrinsically unstable ultra-thin matter.

Professor Geim and his colleagues believe that the membranes they have created can be used like sieves, to filter light gases through the atomic mesh of the chicken wire structure, or to make miniature electro-mechanical switches.

It’s also thought it may be possible to use them as a non-obscuring support for electron microscopy to study individual molecules.

This has significant implications for the development of medical drugs, as it will potentially allow the rapid analysis of the atomic structures of bio-active complex molecules.

“This is a completely new type of technology – even nanotechnology is not the right word to describe these new membranes,” said Professor Geim.

“We have made proof-of-concept devices and believe the technology transfer to other areas should be straightforward. However, the real challenge is to make such membranes cheap and readily available for large-scale applications.”

A second article this week on the subject by the same team suggests the work could be used for transistors.

Another group this week at Cornell

found that a single sheet of graphene, a form of carbon atoms in a plane just one atom thick, can be isolated and used as an electromechanical resonator.

New UD technology removes viruses from drinking water

02nd March 2007

Here’s an interesting disinfectant that might be appropriate fit for several different problems. The key take away is that

The elemental or “zero-valent” iron (Fe) used in the technology is widely available as a byproduct of iron and steel production, and it is inexpensive, currently costing less than 40 cents a pound (~$750/ton). Viruses are either chemically inactivated by or irreversibly adsorbed to the iron, according to the scientists.

“In 20 minutes, we found 99.99 percent removal of the viruses,” Chiu said. “And we found that removal of the viruses got even better than that with time, to more than 99.999 percent.”

The elemental iron also removed organic material, such as humic acid, that naturally occurs in groundwater and other sources of drinking water.

I’m also thinking that Fe might also have a pretty stiff charge that would ward off some dissolved salts.

The full article is below.

New UD technology removes viruses from drinking water

3:21 p.m., Feb. 26, 2007–University of Delaware researchers have developed an inexpensive, nonchlorine-based technology that can remove harmful microorganisms, including viruses, from drinking water.

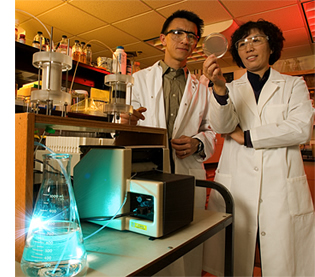

UD’s patented technology, developed jointly by researchers in the College of Agriculture and Natural Resources and the College of Engineering, incorporates highly reactive iron in the filtering process to deliver a chemical “knock-out punch” to a host of notorious pathogens, from E. coli to rotavirus.

The new technology could dramatically improve the safety of drinking water around the globe, particularly in developing countries. According to the World Health Organization (WHO), over a billion people–one-sixth of the world’s population–lack access to safe water supplies.

Four billion cases of diarrheal disease occur worldwide every year, resulting in 1.8 million deaths, primarily infants and children in developing countries. Eighty-eight percent of this disease is attributed to unsafe water supplies, inadequate sanitation and hygiene.

In the United States, viruses are the target pathogenic microorganisms in the new Ground Water Rule under the Environmental Protection Agency’s Safe Drinking Water Act, which took effect on Jan. 8.

“What is unique about our technology is its ability to remove viruses–the smallest of the pathogens–from water supplies,” Pei Chiu, an associate professor in UD’s Department of Civil and Environmental Engineering, said.

Chiu collaborated with Yan Jin, a professor of environmental soil physics in UD’s plant and soil sciences department, to develop the technology. They then sought the expertise of virologist Kali Kniel, an assistant professor in the animal and food sciences department, who has provided critical assistance with the testing phase.

“A serious challenge facing the water treatment industry is how to simultaneously control microbial pathogens, disinfectants such as chlorine, and toxic disinfection byproducts in our drinking water, and at an acceptable cost,” Chiu noted.

Viruses are difficult to eliminate in drinking water using current methods because they are far smaller than bacteria, highly mobile, and resistant to chlorination, which is the dominant disinfection method used in the United States, according to the researchers.

Of all the inhabitants of the microbial world, viruses are the smallest–as tiny as 10 nanometers. According to the American Society for Microbiology, if a virus could be enlarged to the size of a baseball, the average bacterium would be the size of the pitcher’s mound, and a single cell in your body would be the size of a ballpark.

“By using elemental iron in the filtration process, we were able to remove viral agents from drinking water at very high efficiencies. Of a quarter of a million particles going in, only a few were going out,” Chiu noted.

The elemental or “zero-valent” iron (Fe) used in the technology is widely available as a byproduct of iron and steel production, and it is inexpensive, currently costing less than 40 cents a pound (~$750/ton). Viruses are either chemically inactivated by or irreversibly adsorbed to the iron, according to the scientists.

Technology removes 99.999 percent of viruses

The idea for the UD research sprang up when Jin and Chiu were discussing their respective projects over lunch one day.

Since joining UD in 1995, Jin’s primary research area has been investigating the survival, attachment and transport behavior of viruses in soil and groundwater aquifers. One of the projects, which was sponsored by the American Water Works Association Research Foundation, involved testing virus transport potential in soils collected from different regions across the United States. Jin’s group found that the soils high in iron and aluminum oxides removed viruses much more efficiently than those that didn’t contain metal oxides.

“We knew that iron had been used to treat a variety of pollutants in groundwater, but no one had tested iron against biological agents,” Chiu said. So the two researchers decided to pursue some experiments.

With partial support from the U.S. Department of Agriculture and the Delaware Water Resources Center, through its graduate fellowship program, the scientists and their students began evaluating the effectiveness of iron granules in removing viruses from water under continuous flow conditions and over extended periods. Two bacteriophages–viruses that infect bacteria–were used in the initial lab studies.

Since then, Kniel has been documenting the technology’s effectiveness against human pathogens including E. coli 0157:H7, hepatitis A, norovirus and rotavirus. Rotavirus is the number-one cause of diarrhea in children, according to Kniel.

“In 20 minutes, we found 99.99 percent removal of the viruses,” Chiu said. “And we found that removal of the viruses got even better than that with time, to more than 99.999 percent.”

The elemental iron also removed organic material, such as humic acid, that naturally occurs in groundwater and other sources of drinking water. During the disinfection process, this natural organic material can react with chlorine to produce a variety of toxic chemicals called disinfection byproducts.

“Our iron-based technology can help ensure drinking-water safety by reducing microbial pathogens and disinfection byproducts simultaneously,” Chiu noted.

Applications in agriculture and food safety

Besides helping to safeguard drinking water, the UD technology may have applications in agriculture.

Integrated into the wash-water system at a produce-packing house, it could help clean and safeguard fresh and “ready to eat” vegetables, particularly leafy greens like lettuce and spinach, as well as fruit, according to Kniel.

“Sometimes on farms, wash-water is recirculated, so this technology could help prevent plant pathogens from spreading to other plants,” she said.

This UD research underscores the importance of interdisciplinary study in solving problems.

“There are lots of exciting things you can discover working together,” Jin said, smiling. “In this project, we all need each other. Pei is the engineer and knows where we should put this step and how to scale it up. I study how viruses and other types of colloidal particles are transported in water, and Kali knows all about waterborne pathogens.

“Our hope is that the technology we’ve developed will help people in our country and around the world, especially in developing countries,” Jin noted.

Currently, the Centre for Affordable Water and Sanitation Technology in Calgary, Canada, is exploring use of the UD technology in a portable water treatment unit. Since 2001, the registered Canadian charity has provided technical training in water and sanitation to more than 300 organizations in 43 countries of the developing world, impacting nearly a million people.

The University of Delaware is pursuing commercialization opportunities for the research. Patents have been filed in the United States, Canada, France, Germany and Switzerland. For more information, contact Bruce Morrissey, UD director of technology development, Office of the Vice Provost for Research and Graduate Studies, at [brucem@udel.edu] or (302) 831-4230.

Article by Tracey Bryant

Photos by Kathy Atkinson

Nanotube Heal Thyself

23rd February 2007

Last July I posted about how “Scientists at Argonne National Labs are modeling for electrical properties by adding defects in carbon nanotubes”. I thought this was interesting because the:

methodology looks like it could be readily adopted for desal research by adjusting the charge on a carbon nanotube to screen for Na or Cl–as was done for Hydrogen production purposes by collaborating researchers from UT and the Research Triangle Institute in the Research Triangle NC.

Now consider this article below about how an imperfection moves along the carbon nanotube. Perhaps the charge of a carbon nanotube couldn’t be induced to change as the blemish moved up and down the nanotube.

Nanotube, heal thyself

Atomic blemishes move, repairing molecular skin in their wakeHOUSTON, Feb. 15, 2007 — Pound for pound, carbon nanotubes are stronger and lighter than steel, but unlike other materials, the miniscule cylinders of carbon – which are no wider than a strand of DNA – remain remarkably robust even when chunks of their bodies are blasted away with heat or radiation. A new study by Rice University scientists offers the first explanation: tiny blemishes crawl over the skin of the damaged tubes, sewing up larger holes as they go.

“The shape and direction of this imperfection does not change, and it never gets any larger,” said lead researcher Boris Yakobson, professor of mechanical engineering and materials science and of chemistry. “We were amazed by it, but upon further study we found a good explanation. The atomic irregularity acts as a kind of safety valve, allowing the nanotube to release excess energy, in much the way that a valve allows steam to escape from a kettle.”

The research appears Feb. 16 issue of in Physical Review Letters.

Carbon nanotubes are hollow cylinders of pure carbon that measure about a billionth of a meter, or one nanometer, across. They are much longer than they are wide, akin in shape to 100-foot garden hose, and they’re 100 times stronger than steel at one-sixth the weight.

The carbon atoms in nanotubes are joined together in six-sided hexagons, so when scientists sketch out the arrangement on paper, nanotubes look something like a rolled up tube of chicken wire. Yakobson’s “smart repair machine” is a deformity, a blemish in this pattern. The blemish consists of a five-sided pentagon joined to a seven-sided heptagon and contains a total of ten atoms. Yakobson, who specializes in using computers to decipher the atomic pecularities of materials, discovered several years ago that mechanically stressed nanotubes – like those being pulled very hard from both ends – are predisposed to develop these 5/7-defects due to the complex interplay of thermodynamic forces at work in the nanotube.

In the latest study, Yakobson, research associate Feng Ding and students examined the effects of other types of stress, including exposure to heat and radiation. The tests confirmed the predisposition of nanotubes to develop the 5/7 blemishes, and they revealed the blemishes’ unexpected healing powers.

“The 5/7-blemishes move across the surface of the nanotube like a steamship, giving off puffs of carbon gas,” said Ding. “In their wake, the skin of the tube appears pristine, in its characteristic hexagonal arrangement.”

Yakobson said the blemishes consume all larger defects, and chug along indefinitely, rearranging atoms and healing the skin of the damaged nanotubes. This explains how nanotubes retain their strength, even when severely damaged. But the healing comes with a price.

“In their role as a safety valve, the 5/7-steamers give off energy and mass, which is released as pairs of gaseous carbon atoms,” Yakobson said. “Since they never change shape or stop moving, they ever so slowly eat away the surface of the nanotube, one pair of atoms at a time.”

Yakobson said the 5/7-blemishes turn when they reach the end of the nanotube and return in the opposite direction. In fact, there’s only one thing that can stop them: another 5/7 blemish. If two of the blemishes run headlong into one other, they cancel each other out and disappear.

Research co-authors include graduate students Kun Jiao and Mingqi Wu.

The research was supported by the Office of Naval Research, the National Science Foundation and the Robert A. Welch Foundation.

Controlling the Movement of Water Through Nanotube Membranes

16th February 2007

Last June I posted in Computer Power in 5-10 Years — that computers 1000 times faster than todays computers will be available in 5-10 years. This week Intel unveiled the first Teraflop chip. It won’t be available for 5 years or more. First teraflop speeds were achieved at Sandia Labs 10 years ago using building sized computers. Remember this stuff speeds up the rate at which things happen. Its in part the accelerating speed of the computers that give men like Mihail Roco, senior advisor for the nanotechnology to the National Science Foundation and a key architect of the National Nanotechnology Initiative…such confidence about the accelerating pace of developments in nano technology.

What about those developments?

I mentioned charge in passing during the post on the work of LLNL researchers last year. This week there were two different groups that created membranes using charge and a third that made a supercondenser made of nanotubes.The first is from the University of Rochester. Their post will appear in Nature. They have created a membrane that’s 50 atoms thick. Its NOT a carbon nanotube but I think the work is interesting because it suggests that the charge properties of the carbon nanotubes are not a function of the shape of the nanotubes–and maybe not even the size of the nanotubes. Read this second piece to see how scientists at MIT charge carbon nanotubes used to create the next generation batteries that charge up instantly. The third piece is the most interesting. A group at Rensselaer Polytechnic Institute announced that they had found a way to precisely control the flow of water through carbon nanotubes by adjusting the carbon nanotube membrane charge. How did they create the membranes? They may have used a printing method developed by another Rensselaer Polytechnic Institute team–or another by method developed by a Northwestern Team. But I can’t be sure. Anyhow, here’s the post. (see me comment after the post.)

bV = parseInt(navigator.appVersion); if (bV >= 4) window.print();

| Controlling the Movement of Water Through Nanotube Membranes |

|

Precise control of water transport through a nanotube membrane is demonstrated by a novel electro-chemical approach. Credit: Rensselaer Polytechnic Institute By fusing wet and dry nanotechnologies, researchers at Rensselaer Polytechnic Institute have found a way to control the flow of water through carbon nanotube membranes with an unprecedented level of precision. |

| The research, which will be described in the March 14, 2007 issue of the journal Nano Letters, could inspire technologies designed to transform salt water into pure drinking water almost instantly, or to immediately separate a specific strand of DNA from the biological jumble.

Nanotube membranes have fascinated researchers with their combination of high flow rates and high selectivity, allowing them to filter out very small impurities and other organic materials like DNA and proteins from materials with high water content. The problem is that nanotube arrays are hydrophobic, strongly repelling water. “We have, at a very fundamental level, discovered that there is a new mechanism to control water transport,” said Nikhil Koratkar, associate professor of mechanical engineering at Rensselaer and lead author of the paper. “This is the first time that electrochemical means can be used to control the way that the water interacts with the surface of the nanotube.” A group of Rensselaer researchers led by Koratkar has found a way to use low-voltage electricity to manipulate the flow of water through nanotubes. Control of water’s movement through a nanotube with this level of precision has never been demonstrated before. “In this century one of the big challenges is how to get clean drinking water,” Koratkar said. “If you can remove salt from water you can solve this problem. Nature does this all the time. The first step to getting to this process is to control the flow of water through nanochannels, which we have now successfully demonstrated. This is the starting part of the research. The next step would be to capture specific proteins, DNA, or impurities within the water with specifically designed nanotubes.” The researchers discovered that when the nanotube’s membrane is given a small positive potential of only 1.7 volts, and the water is given a negative potential, the nanotubes quickly switch from repelling water to pumping water through the tube. When the charge on the water is raised, the water flows through at an exponentially faster rate. When the experiment is reversed with a negatively charged nanotube, it takes much higher voltage (90 volts) to move the water through the tube. By simply reversing the polarity of the nanotubes, the team found that they could actually start and stop the flow of water through the tube. When a small positive charge is administered the water moves through the tube, and when that charge is reversed the water flow stops. The researchers determined that the nanotube walls had been electrochemically oxidized as a result of water electrolysis, meaning that oxygen atoms had coated the surface of the nanotubes enabling the movement of water through the tube. Once the charge is reversed, oxidation stops and the water can no longer flow through the unoxidized portion of the tube. The researchers also discovered that they could control the rate of water flow through nanotubes sitting directly next to each other, allowing one tube to pump quickly while the one next to it didn’t pump water at all. Such an extreme difference in water absorption so close together is unprecedented, and could have major implications for time-released drug coatings, lab-on-a-chip devices, and water capture that mimics some of nature’s most efficient water-harvesting materials. The research is the first step to creating nanotube devices built to filter out specific elements from water and organic materials. With this enabling research in place, more efficient micro-filtration and separation techniques can be created for environmental restoration, the production of safe drinking water, biomedical research, and advanced circuitry. Pulickel Ajayan, the Henry Burlage Professor of Materials Science and Engineering at Rensselaer and a world-renowned expert in fabricating nanotube materials, collaborated with Koratkar on this project. Four other Rensselaer researchers were involved with the research: Saroj Nayak, associate professor of physics; post-doctoral researcher Lijie Ci; and doctoral students Li Chen and Zuankai Wang. Source: Rensselaer Polytechnic Institute |

|

This news is brought to you by PhysOrg.com |

friends…just for giggles,… show them this piece on programmable water. And then mention the work above.